Autoclave Gaskets

Autoclave Gaskets Specification

- Hardness

- 65 5 Shore A

- Temperature Resistance

- Up to 250C (depending on material)

- Medium

- Steam, Air, Gases

- Vaccum Range

- Down to 740 mm Hg

- Working Temperature

- -40C to +250C

- Pressure Resistance

- Up to 150 psi

- Gasket Coefficient

- Low compression set

- Standard

- ASTM D2000 / IS 638

- Material

- Silicone Rubber, EPDM, Neoprene, Viton

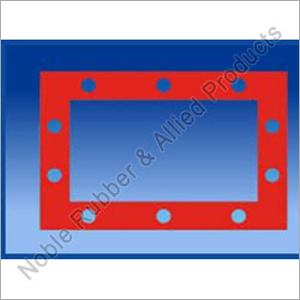

- Shape

- Round, Rectangular, Door Type

- Outer Ring

- Optional (available on request)

- Inner Ring

- Optional (available on request)

- Size

- Custom sizes available as per requirement

- Application

- Used in autoclaves for steam, air, or other gas sealing

- Thickness

- 3 mm to 25 mm

- Tensile Strength

- 8 MPa minimum

- Surface Type

- Smooth / Plain

- Finish

- Molded, Extruded

- Chemical Resistance

- Excellent with acids, alkalis and solvents depending on material

- Lifespan

- Long durability, reusable

- Color

- White, Red, Black (as per material and application)

- Elongation at Break

- 300% minimum

- Installation Type

- Groove Mounted or Clamp Fitted

- Durometer Range

- 40 to 80 Shore A (other range available on request)

Autoclave Gaskets Trade Information

- Supply Ability

- Delivery Time

- 1-7 Days

- Sample Available

- Yes

- Packaging Details

- Wooden Packaging/boxes

- Main Export Market(s)

- Middle East

- Main Domestic Market

- All India

- Certifications

- MSME

About Autoclave Gaskets

As a reckoned business name, we are actively instrumental in delivering a broad variety of Autoclave Gaskets. Offered range is act as a barrier by providing excellent sealing and resists the leakage of oil, solvent and other liquid and gaseous item. Offered range is available in different thickness and dimensions according ourclient individual requirements. Moreover our offered range is highly acknowledged in market for its long lasting sealing and less maintenance. Apart from this our client can avail these Autoclave Gaskets from us at reasonable price and in given time frame.

Features:

- Thermal resistance

- Dimensional accuracy

- Application specific structure

- Smooth finish

Exceptional Chemical and Temperature Resistance

These autoclave gaskets deliver excellent resistance to acids, alkalis, and solvents, ensuring stable performance even under harsh autoclave conditions. Depending on material selection (such as silicone, EPDM, Neoprene, or Viton), they withstand continuous exposure to temperatures from -40C up to 250C, maintaining integrity and sealing efficiency for demanding applications.

Precision Engineered for Versatile Sealing Needs

Gaskets are available in a variety of shapesround, rectangular, and door-specific formssuitable for different autoclave designs. The smooth and plain surfaces, combined with a low compression set, facilitate secure sealing for steam, air, and gases. Custom sizes and optional inner or outer rings further enhance application flexibility.

Durable and Reusable Performance

Installed via groove mounting or clamp fitting, these gaskets offer long-lasting durability and reliability. With an elongation at break of minimum 300% and high tensile strength, they remain reusable across multiple autoclave operation cycles, minimizing the need for frequent replacements and ensuring cost-effective maintenance for users.

FAQs of Autoclave Gaskets:

Q: How should autoclave gaskets be installed for optimal sealing performance?

A: Autoclave gaskets can be installed using groove mounting or clamp fitting methods. Select the appropriate installation based on your autoclaves design to ensure a tight, leak-proof seal for steam, air, or gases.Q: What materials are available for these autoclave gaskets, and how does material choice affect application?

A: Gaskets are made from silicone rubber, EPDM, Neoprene, and Viton. Material choice influences chemical resistance, temperature tolerance, and suitability for specific mediums such as steam, air, or gases.Q: When is it recommended to use custom-sized or shaped gaskets?

A: Custom-sized or specially shaped gaskets are ideal when standard solutions do not match your autoclaves design, ensuring precise fitting and sealing efficiency for unique chambers or door types.Q: Where can these gaskets be applied, and what environments are suitable?

A: Autoclave gaskets are suitable for use in laboratories, medical sterilizing units, and industrial autoclaves where reliable steam, air, or gas sealing is required under high pressure and temperature conditions.Q: What is the process for ordering gaskets with optional inner or outer rings?

A: To order gaskets with inner or outer rings, simply request the desired option along with your required specifications when contacting the manufacturer, supplier, or exporter.Q: How do the gaskets benefit long-term operations and maintenance?

A: Durable and reusable by design, the gaskets maintain a low compression set and long lifespan, reducing replacement frequency and providing cost savings in repeated high-temperature autoclave cycles.Q: What standards do these autoclave gaskets meet, and why is this important?

A: The gaskets are manufactured in compliance with ASTM D2000 and IS 638 standards, ensuring quality, consistency, and safety across various industrial and laboratory applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Gaskets Category

Silicone Rubber Gaskets

Price 110 INR

Minimum Order Quantity : 50 Pieces

Shape : Other, Round, Oval, Rectangular, Customized

Pressure Resistance : Up to 10 Bar

Thickness : 1 mm to 10 mm

Application : Sealing, Insulation, Pharmaceutical & Food Industries, Electronics, Automotive, Chemical Processing

Custom Rubber Gaskets

Price 2700 INR

Minimum Order Quantity : 18 Sets

Shape : Round, Other

Pressure Resistance : High

Thickness : Variable

Application : Industrial

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free