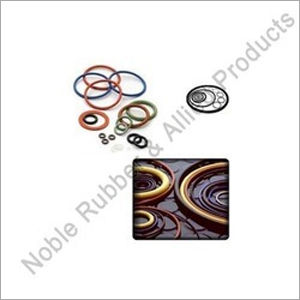

O Ring

O Ring Specification

- Usage & Applications

- Widely used as sealing elements in hydraulic, pneumatic systems, automotive, industrial machinery, and plumbing applications

- Flame Resistance Level

- Standard (special grades available)

- Color

- Black

- Part Type

- Sealing Gasket

- Style

- Circular/Solid

- Ash %

- Less than 0.5%

- Natural Rubber

- Available (also in NBR, EPDM, etc.)

- Width

- Standard sizes (customizable)

- Components

- Single ring structure

- Product Type

- O Ring

- Feature

- Excellent sealing, oil resistance, abrasion resistance

- Density

- 1.6 Gram per cubic centimeter(g/cm3)

- Tensile Strength

- 12~20 MPa (depends on material)

- Material

- Rubber (NBR, EPDM, Viton, Silicone, etc.)

- Hardness

- Shore A 705

- Surface Finish

- Smooth

- Thickness

- 1 mm to 10 mm (varies by size)

- Weight

- Depends on size

- Tolerance

- 0.1 mm

- Temperature Resistance

- -40C to +120C (varies by material)

- Length

- Circular shape, no linear length

- Water Absorption

- Low

- Rubber Type

- NBR/EPDM/Viton/Silicone

- Resistance level

- High resistance to oil, chemicals, and wear

- Size

- Available in various standard and custom sizes

- Compression Ratio

- 15-30%

- Diameter

- Customized

- Thermal Conductivity

- Low

- Shape

- Round continuous ring

- Minimum Order Quantity

- 100 pieces

- OEM/Customization

- Available

- Lead Time

- 5-10 working days

- Elongation at Break

- 200%~500%

- Service Life

- Long service life under normal conditions

- Chemical Resistance

- Good (depends on selected elastomer)

- Ozone Resistance

- Excellent (EPDM material)

- Packaging Type

- Plastic bag, box, or as required

- Operating Pressure

- up to 10 MPa

- Shore Hardness Range

- Shore A 40-90 (customizable)

O Ring Trade Information

- Minimum Order Quantity

- 25 Pieces

- Supply Ability

- Piece

- Delivery Time

- 1-7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packging/ Boxes

- Main Export Market(s)

- Middle East

- Main Domestic Market

- All India

- Certifications

- MSME

About O Ring

Without compromising on the client needs and quality of our products, we have come up with a wide range of O Ring that find its application in various hydraulic transmission,fuel handling system, chemical processing industries and other industry for sealing purpose. To meet the different requirements of our customer our offered range is available in different sizes and finish. Our quality controller checked offered range on different industrial parameters to ensure its durability and reliability. Our client can avail O Ring from us at rock bottom price.

Features:

- High friction and abrasion resistance

- Resistant to rust and impact

- Their robust construction enhance their life

- Excellent compression set

Exceptional Customization and Material Options

Choose from various elastomers including EPDM, NBR, Viton, and Silicone to match your specific sealing requirements. Customizable hardness and size ensure suitability for diverse hydraulic, pneumatic, automotive, and industrial uses. With OEM options available, these O Rings cater to unique project specifications while maintaining rigorous quality standards for consistent performance.

High Performance in Challenging Environments

Our O Rings excel in environments with stringent pressure demands, operating up to 10 MPa, and temperature ranges from -40C to +120C depending on the material chosen. They resist ozone, oil, and abrasion thanks to their well-engineered rubber compounds and smooth surface finish, ensuring long service life and low maintenance needs for critical machinery applications.

FAQs of O Ring:

Q: How can I customize the size, hardness, or material of the O Ring for my application?

A: Customization for O Rings is available on size, Shore hardness (A 40-90), material (NBR, EPDM, Viton, Silicone, or Natural Rubber), and packaging. Specify your requirements when placing an order, and our team will manufacture rings to match your application needs. OEM services are also offered for specialized projects.Q: What is the typical lead time for delivery and what is the minimum order quantity?

A: The minimum order quantity is 100 pieces. Standard lead time ranges from 5 to 10 working days, depending on customization and order volume. For large or uniquely specified orders, delivery time may vary and can be confirmed upon quotation.Q: Where are these O Rings commonly used and what benefits do they offer in such applications?

A: O Rings are widely used as sealing elements in hydraulic and pneumatic systems, automotive components, industrial machinery, and plumbing equipment. Their benefits include excellent sealing under high pressure, resistance to oil and chemicals, long service life, and adaptability to varying temperatures.Q: What is the process for selecting the right elastomer for specific chemical resistance needs?

A: Selecting the right elastomer depends on the chemicals and operating conditions your O Ring will encounter. EPDM is ideal for ozone and weather resistance, while NBR and Viton suit oil and fuel environments. Consult our technical team with details about your application for expert material recommendations.Q: How do the packaging options work for shipping/export?

A: O Rings can be packed in plastic bags, boxes, or tailored packaging as per customer requirements. These options are designed to ensure protection during transit. For export orders, additional packaging considerations can be accommodated to comply with international shipping standards.Q: What is the expected service life and how do O Rings maintain performance over time?

A: O Rings deliver a long service life under normal conditions due to high-quality elastomer compounds, precise manufacturing tolerances (0.1 mm), and excellent resistance to wear, oil, ozone, and chemicals. Regular inspection and appropriate material selection help ensure consistent performance in critical sealing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in O Rings Category

Ptfe O Ring

Price 1100 INR

Minimum Order Quantity : 12

Usage & Applications : Used in sealing applications in various industries

Color : White

Temperature Resistance : High temperature resistance

Feature : High chemical resistance and durability

Send Inquiry

Send Inquiry Send SMS

Send SMS